RISK ASSESSMENT MATURITY IN SMALL MANUFACTURING

How visual tools can shape decision-making in small shops

As products and supply chains become more complex, unmanaged operational risk adversely affects customers and ultimately the end user. This is why modern standards are placing more emphasis on making risk visible, deliberate, and actively managed.

Early in a company’s life, most operational risk assessment lives in people, not in processes. The challenge is transforming experience into a visible, shared discipline as complexity increases and decisions begin to span more people, more suppliers, and more customers. This transition marks the difference between informal risk handling and mature operational risk management in manufacturing systems. In mature organizations, risk assessment is not used only for compliance. It is used to train thinking, build shared judgment, and create a learning system that improves reliability as they grow.

For small manufacturers, this creates a practical question:

How do you build a risk process that protects the end user, satisfies modern standards, and still fits the reality of a growing shop?

Early in a company’s life, most operational risk lives as tacit knowledge. It lives in judgment, memory, and informal conversations among team members. Team members know where fragile suppliers, sensitive processes, and single-point dependencies exist. As complexity increases, that is no longer enough.

Effective risk management starts with culture and habit, not with software or paperwork. Before formal systems, you first train how people think through repeated, visible practice:

What could go wrong? How likely is it? What is the impact if it does?

One way to train this thinking is through simple visual management and communication.

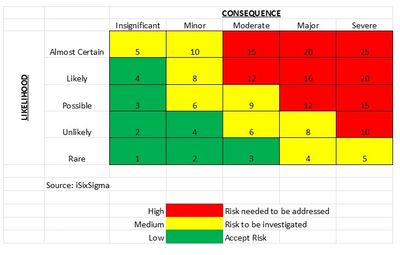

A basic green–yellow–red risk assessment matrix forces three things to happen during contract review and job planning:

· risks must be named,

· their likelihood and consequence must be discussed,

· and a conscious decision must be made before proceeding.

Shown in the picture is an example of a simple risk assessment matrix. Several of these exist on the internet.

Over time, these simple tools create a shared language across the team. A green risk is understood immediately. A yellow risk triggers discussion. A red risk requires mitigation and/or escalation. Over time, those habits become structured methods and those methods become part of daily management. The goal is to make better decisions earlier.

This is not unique to small companies. Even the most sophisticated manufacturing systems continue to rely heavily on visual management. They use advanced automation, analytics, and enterprise systems, but they do not abandon simple visual methods. The reason is not tradition. It is cognition. Digital systems are effective at optimizing known processes, but visual management plays an important role in how humans notice abnormalities, surface weak signals, and discuss risk early. Technology changes. Thinking disciplines do not.

Now consider a common operational case. A planner may recognize that a particular job involves a new or unproven process, a tight tolerance near machine capability, or a complex first-article feature. When that risk is captured in the job-level risk assessment and shows up as a red color, the team will know it is important to mitigate. Mitigation may be simple: add an extra verification step, plan additional proving runs, or adjust sequencing. The point is not the form itself, but to make important risks visible so the team acts deliberately.

As organizations grow, operational risk assessment naturally evolves. It moves from informal judgment, to simple visual tools, to structured job-level evaluation, and eventually to system-level risk management tied to planning and execution. For small manufacturers, the path is not to adopt complex tools too early, nor to avoid structure altogether. The path is to build habits first, then systems, and then maturity. When risk is treated this way, it becomes not a burden, but a core management capability.

For customers and end users, effective operational risk management is often associated with tangible system-level benefits:

– Higher delivery predictability

– Earlier detection of potential defects

– Fewer late-stage disruptions

– More stable production planning and execution

– Greater confidence in supplier commitments for mission-critical programs

In this sense, risk-based thinking becomes part of the delivered capability, not just an internal control.

In the end, operational risk maturity is not defined by the form used or the tool selected, but by whether the organization is continuously improving how it thinks, plans, and learns as it grows

Prisecter Aerospace and Defense LLC

355 Sacramento St, Auburn CA 95603

Copyright © 2025 Prisecter Aerospace and Defense LLC All Rights Reserved

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.